Jump To: What is an Impeller? | What is an Open Face Impeller? | What is a Closed Face Impeller? | Differences Between Open & Closed Impellers | How to Select an Impeller

Pump impellers are crucial for your centrifugal pump’s functionality. They determine the pressure and velocity of the pumped fluid as well as the type of waste it can pump. Each impeller has a different flow rate, cost, efficiency level and maintenance requirements.

When determining which impeller is best for you, it’s essential to understand the differences between the two. This guide will review those differences and other factors to help you make your decision. Selecting the correct impeller for your application can minimize energy consumption, maximize flow rates, save money and reduce downtime.

What Is an Impeller?

By definition, an impeller is a component of a centrifugal pump that converts the pump’s mechanical energy to kinetic energy. It transfers the energy from the motor to the fluid, increasing its flow rate and pressure.

The part is a rotating iron or steel disc with curved blades or vanes. These blades form a vacuum that sucks the fluid into the center, then pushes it outwards from the center of rotation.

Thanks to the pump’s motor, impellers can rotate at high speeds. When they rotate very fast, they create a centrifugal force that pushes the fluid out and forms a low-pressure area in the center. The low-pressure area sucks in more liquid from the suction, maintaining a continuous flow rate.

There are two types of impellers — open face and closed face. Closed and open face impellers are suited for different applications because they have different blade sizes, orientations and shapes.

What Is an Open Face Impeller?

An open face impeller doesn’t have a back or front wall. Instead, the blades are attached to a central hub and mounted on a shaft. Since they don’t have a wall, they’re weaker and slightly less efficient than closed impellers. Open impellers are excellent for pumping fluids with suspended solids. Food, chemical processing and water treatment industries commonly use open impellers.

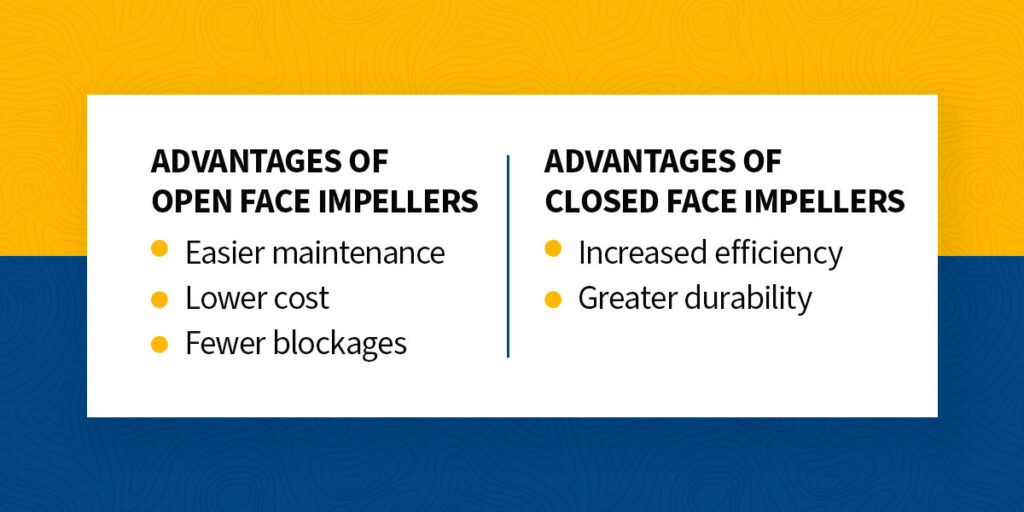

Advantages of open face impellers include:

- Easier maintenance: More parts are visible, so open impellers are easier to clean, inspect for damage and maintain.

- Lower cost: These impellers are easier to manufacture and cost less.

- Fewer blockages: Sand-locking and other blockages occur less frequently with open impellers because there aren’t any small clearance areas, so they’re suitable for small pumps and handling solids.

The disadvantages of open face impellers include the following:

- Less efficient: They are less efficient than other impellers because the flow isn’t guided between the vanes.

- Less durable: Without walls, these impellers are structurally weaker.

- Possible leakage: There’s a gap between the impeller and casing to prevent damage. However, the gap can allow suctioned fluid to leak.

What Is a Closed Face Impeller?

Closed impeller blades have a front and back wall that acts like a cover and encloses them. The walls increase strength and efficiency when pumping solids, but they are more suitable for pumping liquids. Mining, wastewater treatment, and paper and pulp industries commonly use closed face impellers.

Here’s a couple advantages of closed face impellers:

- Increased efficiency: Greater strength makes these options more efficient at pumping solids.

- Greater durability: The walls reduce the load on the shaft, increasing the component’s durability and life span.

Disadvantages of closed face impellers include:

- More difficult to clean and maintain: Clogged closed face impellers are more challenging to clean and maintain than their open face counterparts because you can only see some of the parts.

- More expensive: These impellers are more difficult to manufacture, making them more expensive.

Main Differences Between Open and Closed Face Impellers

While it’s vital to consider efficiency, reliability and maintenance when choosing an impeller, picking the right style for your application is equally important. Here are some of the key differences between open and closed face impellers:

- Closed impellers can handle explosive and volatile fluids — an open impeller cannot.

- You must disassemble a closed impeller to inspect it.

- Closed impellers lose their efficiency over time, but you can maintain an open impeller’s efficiency by adjusting the wear ring’s clearance. The clearance affects the fluid flow rate.

- Open impellers are less likely to clog and easier to clean.

- You can cut an open impeller’s blades to improve capacity.

- Open impellers have a more comprehensive range of speeds than closed impellers.

- The larger the diameter, the more fluid the impeller can handle, but the more energy it requires. A smaller diameter handles less fluid but is more energy-efficient.

How to Select an Impeller

To determine which impeller is best for your application, consider the flow rate, specific gravity, head, viscosity and solids content.

- Flow rate: The flow rate measures the number of gallons a pump can move in a minute or gallons per minute (GPM). A higher GPM indicates a higher flow rate.

- Specific gravity: Specific gravity is the ratio of a substance’s mass to that of an equal volume of water at the same pressure and temperature. Basically, it’s the fluid’s density compared to the density of water. It determines the fluid’s weight, which affects a pump’s efficiency. If your fluid’s specific gravity is higher than one, it requires more power to pump because it’s heavier than water.

- Head: The head is the height the water must reach to get pumped. Often, the GPM is based on the head measurement. For example, 100 GPM at 40 feet of head means the equipment can pump 100 gallons a minute when pumping water at 40 feet.

- Viscosity: Viscosity is a liquid’s resistance to flow, which affects a pump’s efficiency. The higher the substance’s viscosity, the more power is required to pump.

- Solids content: The amount of solid waste in your substance is central to determining your impeller. Most industries choose open face impellers for solids because they don’t clog as easily. At the same time, closed face impellers are more efficient.

Discover GeoForm International’s High-Quality Pumping Equipment

You can only have an impeller with a pump, and you want the best for your dredging equipment. GeoForm International provides dredging and pumping equipment for countless industries. Our pumps and dredges are available in various sizes with stock and customized options.

GeoForm International products deliver remarkable performance and greater durability and efficiency. You can use our pumping and dredging systems for rivers, lakes, ponds, marinas, lagoons and more.

The core of our business is our pumps. Count on them to remove sediment, muck, debris and sludge from the bottom of a waterway smoothly and quickly so you can transport it to another location. Our pumps also power our other products, including dredges, digestor packages and aerators.

Contact us today to learn more about our innovative equipment.