The Dino6 Dredge: Small, Portable, & Powerful!

The Dino6 sediment removal system is comprised of a small, domestically manufactured dredge. The Dino6 measures just over 22 feet long and 6 feet wide and is less than 6 feet tall. With a wet weight of around 4,000 pounds, it is a very lightweight portable dredge, with a low cost of mobilization, and a small environmental footprint.

The Dino6’s mobilization is easier and cleaner than that of a typical 6-inch dredge. Launching and loading the Dino6 is more similar to that of a boat than a conventional dredge or excavator, so using it causes no damage to the shoreline or tracks. Small portable dredging machines ensure thorough cleanup of lakes and ponds without harming wildlife or counter-productively eroding the shoreline.

The Dino6 is similar to a small pontoon boat. It relies on two stainless steel pontoons that are compartmentalized into three independent sections and offer a two-to-one displacement factor for flotation. Easily haul the Dino6 with one trailer to get to remote lakes with damaged shorelines that other dredges would have difficulty accessing.

Our lightweight and portable dredge is powered by a four-cylinder Cummins diesel engine that’s rated at 65 horsepower. With an efficient engine that consumes just 3 GPH of fuel during pumping operations and uses a 30 gallon fuel tank, this dredge is good for hours upon hours of work. Small yet powerful, the Dino6 comes with a high-torque suction boom that can pass debris up to 3 inches in diameter, so you can clear away even the toughest, softball-sized layers of sediment without damage or clogging.

The Dino6 system is simple and easy to operate, excavating sediment with a durable, high-torque and direct-drive cutter head. The system pumps at rates up to 1500 GPM through the highly abrasion-resistant, hydraulic submersible dredge pump. The 6-inch submersible pump installed on this machine is manufactured in-house, so you can be sure of quality craftsmanship you can trust.

In addition, the Dino6 comes with many safety features that will shut down the engine if there’s an issue, such as high temperatures or low fluid levels, so your machine will only operate when it’s fit to do so.

Bodies of Water That Can Benefit From the Dino6

The Dino6 is a powerful small dredge useful for applications in almost all varieties of water bodies, including:

- Containment ponds: Small dredging equipment can help clear away debris and sediment from the bottoms of containment ponds, which exist to prevent toxic wastewater from places like chemical plants and farms from mixing with streams or other bodies of water.

- Decorative ponds: Artificial bodies of water elevate the appearance of places such as golf courses and neighborhoods. Small portable dredges can help keep these ponds in good shape by clearing pollution and keeping the water beautifully clear.

- Lakes: Providing a clean, healthy aquatic lake ecosystem for boating, fishing and more starts with the work of a small floating dredge. The Dino6 clears away sediment and excess nutrients to help combat silt buildup and explosive plant growth.

- Marinas: A small sand dredger such as the Dino6 is perfect for cleaning and beautifying marinas, which can often suffer from sediment buildup due to slow water currents.

1. How deep can the Dino6 work?

A: The Dino6 can excavate at a thirteen-foot depth in standard configuration, a three-foot boom extension allows for an additional two foot of cutting capability.

2. What is the distance I can pump with the Dino6?

A: The Dino6 is rated at 1100 gallons per minute at 50 feet of total dynamic head. Which means it can deliver 1100 gallons per minute 50 feet straight up in the air or (based on frictional losses in the pipeline) it can deliver 1100 GPM over 800 feet horizontally. The specific gravity of your sediment can affect the distance you will be able to pump. Velocity in the pipeline is critical to keeping heavy materials in suspension. A booster pump can be used with this system.

3. Will the Dino6 clear the vegetation off my lagoon?

A: The Dino6 will struggle with many reedy and fibrous forms of vegetation. It is not a difficulty of the pump to put these items into the pipeline, the problem lies with the cutter-bar rotation. The reedy vegetation wraps around the cutter bar and becomes tightly wound and very difficult to remove. The cutter-bar has teeth to loosen material but no cutting action. Lighter surface grasses and other plants which wrap but are easily removed will just present many more short stoppages for clearance. The Dino6 has a working depth of 13 feet.

4. What tolerance for trash and debris should I experience?

A: The submersible pump on the Dino6 can pass debris between baseball and softball size (approx. 3″). The pump and impeller are constructed of ar-400 material that will not be damaged by submerged material including gravel, cobblestones, concrete, tree branches, etc. Materials caught or obstructing the pump are simply removed and operation continues.

5. How do I run the Travel Cable in open water?

A. The are many options for open water rigging, including a spud barge, sinking an anchor or multiple anchors, jetting an anchor into the mud. We generally expect that you will be working towards your shoreline anchor (lots of solid pull) and gingerly back up towards your open water anchor (no load).

6. Do you offer options for a self-propelled Dino6?

A. We realize that there may be few situations where this might be nice, but don’t believe effective pressures can be delivered to the work surface with an outboard efficiently, think of swimming against the side of a pool, you can exert a lot of energy (fuel) but not be putting much force on the wall. The travel cable counters wind, current, pipeline forces and enables certain and accurate tracking of cut paths.

7. How much pipe fits on the trailer?

A. The custom trailer available from Geoform will carry 800 feet of pipe plus the pipe components of the floating discharge on the pipe rack.

8. What is the best way to get the Dino6 into the water?

A: The Dino6 can be launched from the trailer on a boat ramp or sloped ground. Also, it is equipped with lifting eyes welded onto the pontoons for crane or boom truck needs.

9. Does it have booster pump compatibility?

A: One of the three limitations inherent in the use of the Dino6 can be overcome by the use of a properly sized booster pump. Limitations of Pumping distances and extreme elevation changes can be negated with the additional capabilities of a booster pump in the discharge line.

10. How can I tell what type of material I am pumping?

A: Prior to starting a project a sample can be taken of the sediment to be removed, its content will tell you many things about the job including how far you will be able to pump the material (based on weight and velocity needed to maintain suspension), what type of flocculant you will need if using a dewatering device, and what the shrink rate will be for calculating the total yardage of dry solids to be moved or contained.

11. How many cubic yards will the Dino6 move an hour?

A: 1 CY of in situ material per minute is a good baseline for this system. Repositioning, debris clearing, and other stoppages will result in less production. Soft, soupy, gassy materials will exceed these estimates dramatically.

12. How much do I charge and/or how do I bill this work?

A: Please call us to discuss. We are putting together a contractors guide that will help explain the many ways to approach the commercial aspects of this type work and the potential pitfalls.

13. How much does the Dino6 dredge cost?

A: Contact us for more information of pricing and availability.

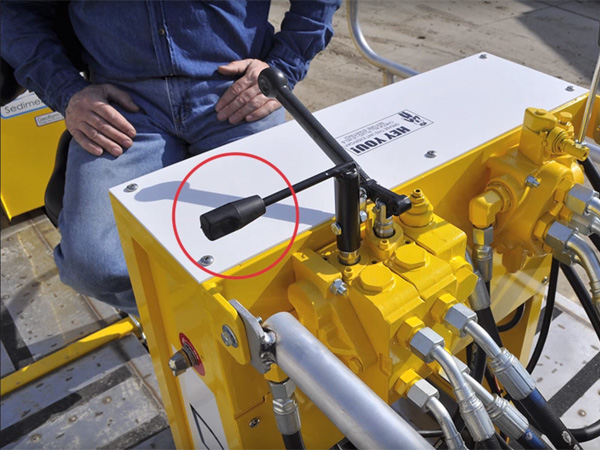

14. What tools should I have on the jobsite when using the Dino6 dredge?

- GREASE GUN; preferably one with a rigid end (rather than a hose)

that makes it easier to grease the cutterbar and pump bearing block.

- SET OF STANDARD HAND TOOLS; for tightening cable clamps, etc.

- SAFETY FLOATATION DEVICES; for persons on dredge and in boats.

- SMALL FLAT-BOTTOM BOAT; for accessing dredge, refueling, etc.

- SMALL PRY BAR

- CABLE CUTTER; for cutting the 1/4” Travel cables.

- SLEDGE HAMMER; for driving anchor stakes.

- WALKIE TALKIE

- 10’ – 12’ PVC PIPE or 2×4 for Depth Gauge

- 5 GALLON BUCKET (onboard storage of tools, towels, dish soap)

- BOTTLE OF DAWN DISH SOAP (for oil sheen if spilled/leaked)

- LENGTHS OF ROPE (tie offs for dredge, pulling discharge pipe, etc.)

- ROLL OF FLAGGING (for marking cable runs in traffic areas)

- FUEL CAN

PRE-OWNED Dino6

1. How do I know when to service my Dino

A: There are several easy ways to tell what moving parts and wear items need to be repaired or replaced based on a variety of circumstances. The best way to know how to properly maintain your Dino product is to call or email us so we can talk you through what services should be performed and why.

2. Where can I buy a used dredge?

A: The availability of Dino6’s on the secondary market varies at times but is perpetually an infrequent occurrence. We believe this is due to our customers having a wonderful ownership experience and continually having work for their machines. The long-lasting materials and durable construction of all of our dredges contribute to a long useful life. The machine is also readily serviceable with a full complement of on-hand components maintained at the factory.

When a used dredge does come on the market it is usually from someone who has just completed a large project and is recouping their initial capital outlay (versus what the cost of renting would have been), someone upgrading to a newer unit, or an entity rotating a machine out of their rental fleet (as we do). Sometimes a Dino6 is an entry vehicle into larger scale work, followed by the purchase of larger machines. There are a great many of these machines in the workplace and we are constantly surprised at how few used Dino6 dredges are available on the secondary market.

Sources of used Dino6 dredges vary as well. We at Geoform like to think we have our finger on the pulse of the secondary market, due to our relationships with owners of Dino6’s around the world. We are occasionally asked to help place these machines. However, a number of these machines have changed hands unbeknownst to us. Anyone interested in finding a used Dino6 would be well advised to give us a call as we are in touch with nearly all of the current owners. Many of the large dredging equipment resellers will also have contacts in the small equipment sector and are worth contacting.

Purchasers of used Dino6 equipment should be in touch with us here at the factory before and after the sale has transacted as we can surely help any potential buyer assess the condition of the machine, the cost of any of the components it may need, and help ensure they get off to a successful and rewarding ownership experience.

UNANSWERED QUESTIONS?

Contact Us

Dino 8

Dino 8  Submersible Pumps

Submersible Pumps